Joe control

Precision Machining, Trusted Worldwide

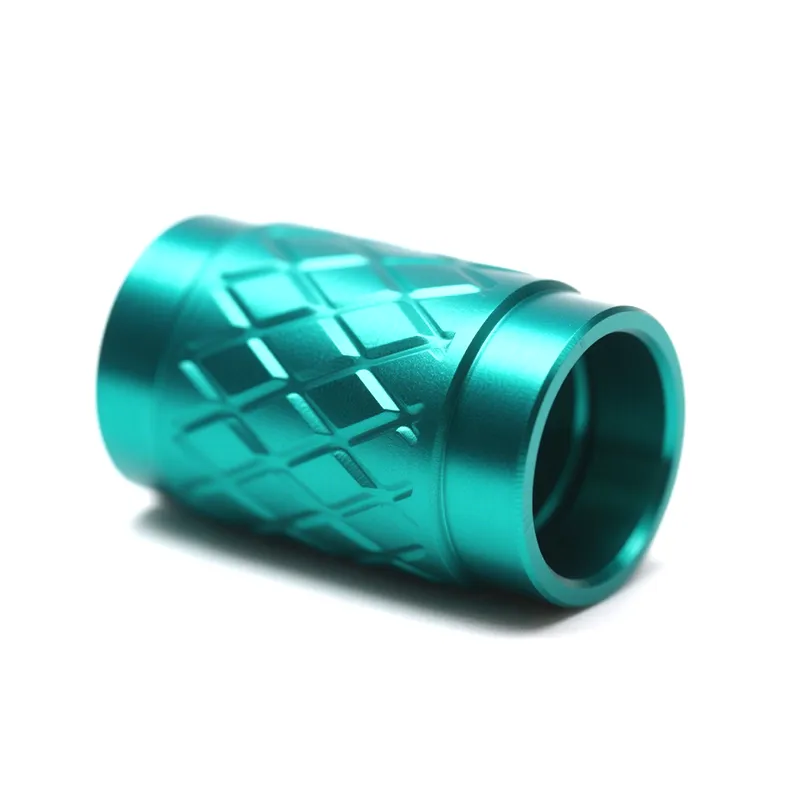

Products

Advanced CNC Solutions for High-End Industries

About Us

Dongguan Haojia Hardware Electronics Co., Ltd. was founded in 2006, located in No.8 Jun Peng Road,Shi Tan Pu,Tang Xia Town,Dongguan City,Guangdong Province,Chin., with 30 CNC laths, 15 turn-milling complex, 40 CNC machines, 32 high-speed punching machines, 3 screw machines, an automated production line and other types of precision processing equipment.

Products are mainly used in medical, automotive, aviation, mobile phone, optics, communications, new energy, automation and other fields, exported to the United States, the European Union, South Korea, Japan, Southeast Asia and other countries, the main customers are: Gac, DJI, BYD, OPPO, Linke Electric and other well-known enterprises, the company has a complete quality assurance system, and passed the IS09001, IATF16949, IS014001 management system certification.

High-Speed, High-Precision, High Trust

Categories

CNC machining is a precise subtractive manufacturing process that uses computer-controlled tools to remove material from a workpiece, creating complex parts with high accuracy and repeatability.

Sheet metal fabrication involves cutting, bending, and assembling thin metal sheets to create parts or structures, commonly used in enclosures, brackets, and automotive components.

Stamping is a high-speed metal forming process where dies press or punch sheet metal into desired shapes, ideal for mass-producing consistent parts like brackets, clips, and panels.

Injection molding is a high-efficiency manufacturing process where molten plastic is injected into a mold, cooled, and ejected, enabling mass production of precise, complex plastic parts with consistent quality.

Empowering Innovation with Precision Parts

Our Advantages

Professional Efficient

According to customer needs, provide personalized non-standard hardware customization services to meet the diverse needs of different customers.

High Accuracy

The precision of CNC machining parts can reach +-0.005mm, and small batches of goods can be fully inspected for each size to ensure that the size is within the tolerance range required by customers.

Rich Experience

The 20 years of OEM/ODM manufacturing experiences, we can not only more clearly understand the requirements of customer, but also provide customer with production solutions.

On Time Delivery

We will make production schedule for our customers when they order, timely feedback on production process, if there are any question, we will communication with customer ahead of schedule, maximum guarantee to customers on time delivery.