Joe control

Share

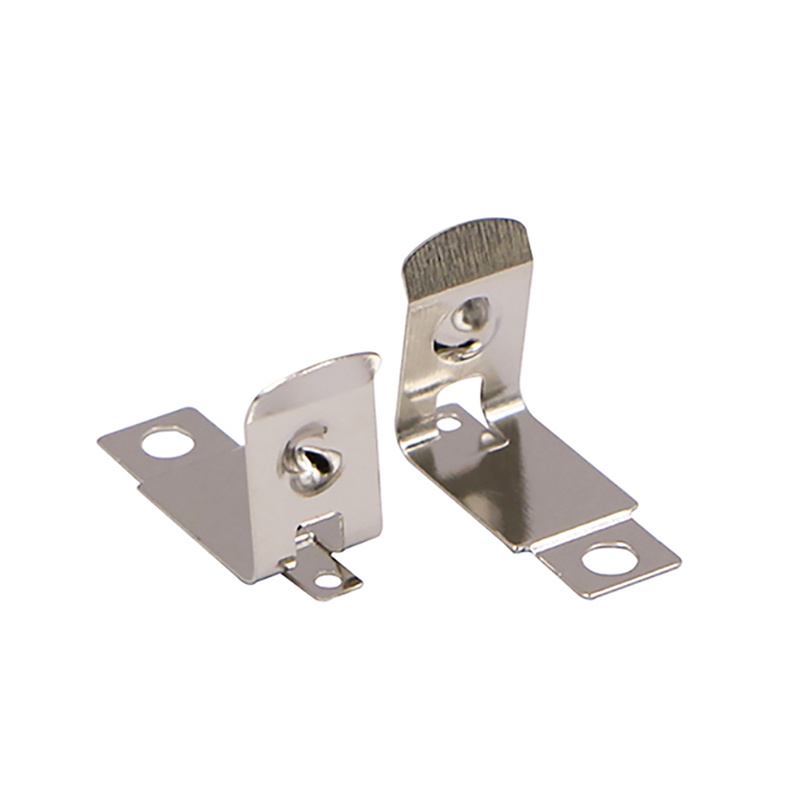

Custom high quality low price steel aluminum stainless steel oem stamping processcnc metal parts manufacturer in china

Still thinking about it? If you want to get a sample first, Please contact us!

Product Categories:

HOME

Keywords:

Haojia

- Description

-

The number of stamping products is large, the price is favorable, the speed is fast, and the stamping is sustainable

Product FAQ

Q

1. What is the customization process?

A

Q

2. How long does the product customization cycle take?

A

Q

3. Which materials can be customized hardware products?

A

Q

4. How accurate can customized products be?

A

Q

5. How to ensure the quality of customized products?

A

Customer reviews

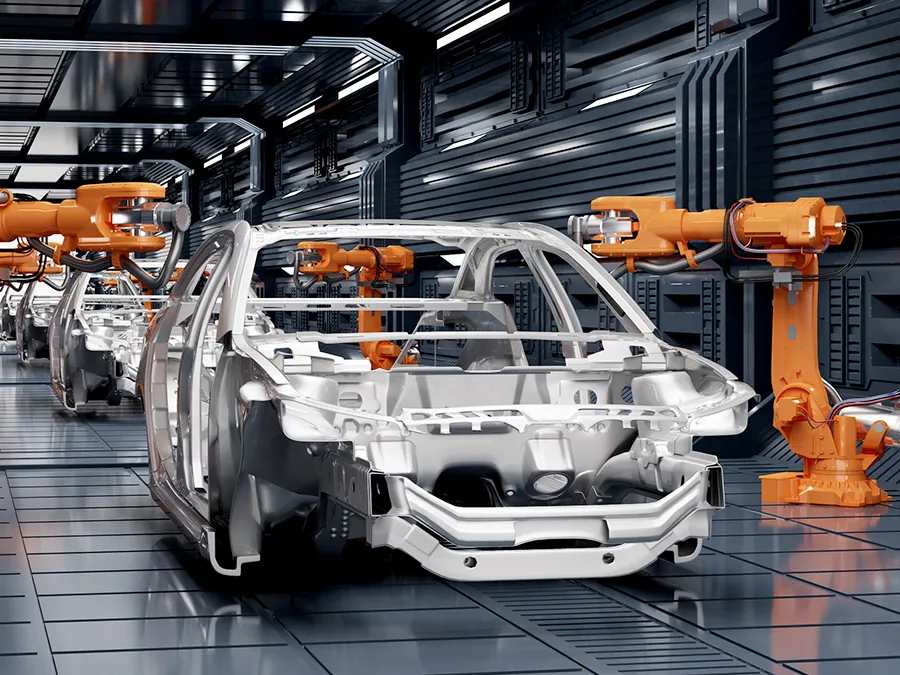

Applications

Medical

Automotive

Aviation

Mobile Phone

Optics

Communications

Advantage-Why Choose Us?

High Accuracy

The precision of CNC machining parts can reach +-0.005mm, and small batches of goods can be fully inspected for each size to ensure that the size is within the tolerance range required by customers.

Rich Experience

The 20 years of OEM/ODM manufacturing experiences, we can not only more clearly understand the requirements of customer, but also provide customer with production solutions.

On time delivery

We will make production schedule for our customers when they order, timely feedback on production process, if there are any question, we will communication with customer ahead of schedule, maximum guarantee to customers on time delivery.

Certificates

Cases

The 20 years of OEM/ODM manufacturing experiences, we can not only more clearly understand the requirements of customer, but also provide customer with production solutions.

Consultation

We will contact you within one working day. Please pay attention to your email.

Related Products