Joe control

Share

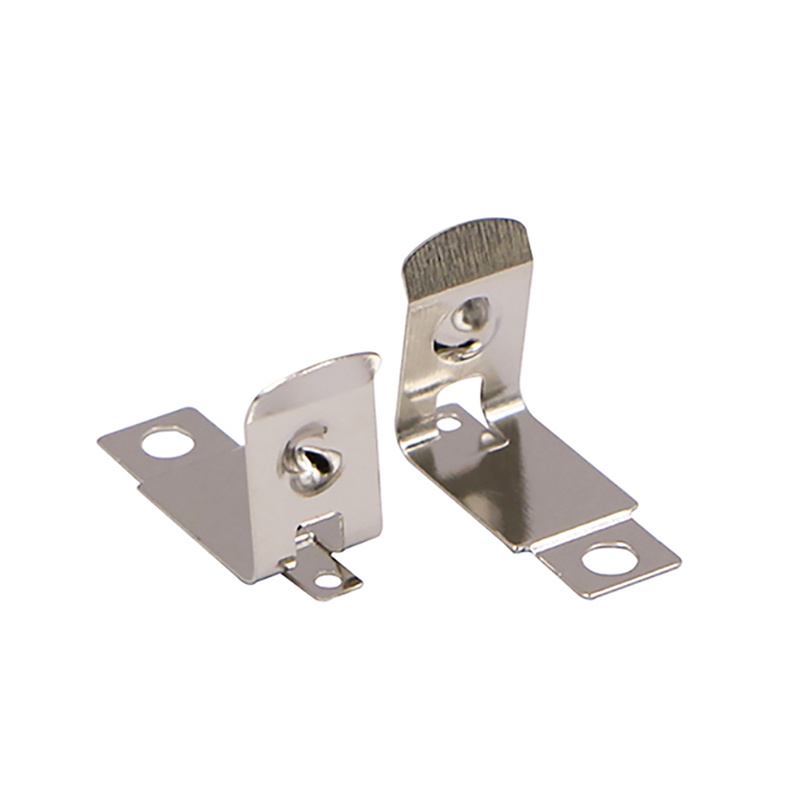

Custom high quality low price steel aluminum stainless steel bending fabrication parts sheet metal fabrication

Still thinking about it? If you want to get a sample first, Please contact us!

Product Categories:

HOME

Keywords:

Haojia

- Description

-

Strictly control each process of sheet metal products to ensure the quality of the final product

We specialize in providing steel aluminum stainless steel bending fabrication parts, leveraging our exquisite craftsmanship and advanced technology to create high-quality products that meet diverse needs across numerous industries.

Extensive Material Selection

We can process materials including steel, aluminum, and stainless steel. Steel, with its high strength and excellent wear resistance, is suitable for applications subject to high pressure and impact, such as building structures and machinery manufacturing. Aluminum, with its lightweight and corrosion-resistant properties, is widely used in aerospace, automotive manufacturing, and other fields with stringent weight requirements. Stainless steel, with its excellent corrosion resistance and aesthetics, is commonly used in food processing, medical devices, and other industries with high hygiene and appearance standards.

Precise Bending Processing

We possess advanced bending equipment and an experienced technical team, enabling us to achieve high-precision bending processes. Whether it's simple arc bending or complex multi-angle, multi-radius bending, we can complete it with precision. Through rigorous process control and quality inspection, we ensure that the bending angle and dimensional accuracy of each component meet customer requirements, providing high-quality products.

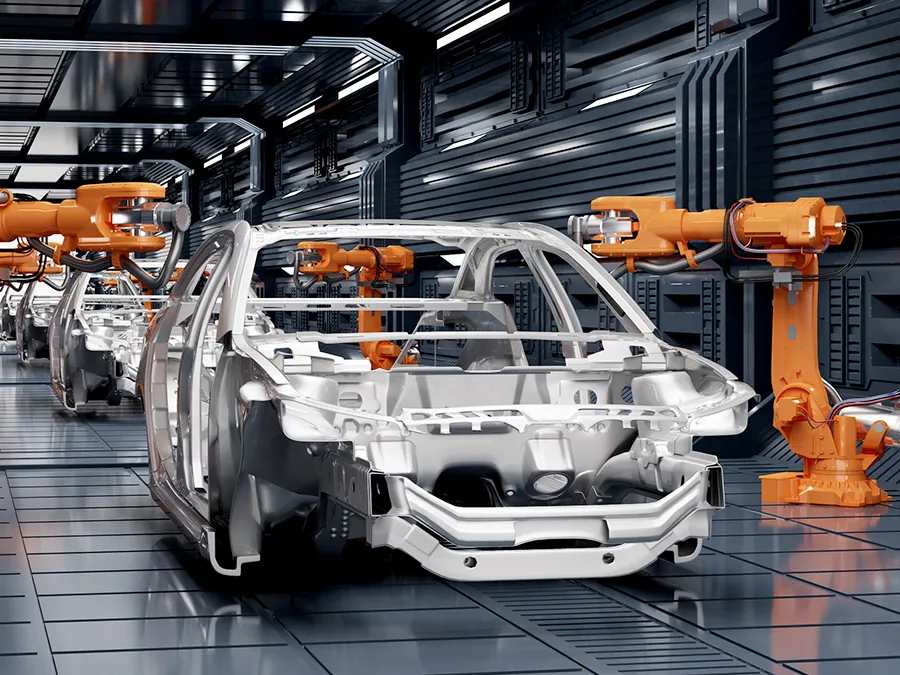

Diverse Application Scenarios

Steel aluminum stainless steel bending fabrication parts have a wide range of applications across various industries. In the construction industry, it can be used to manufacture architectural decorative components, stair railings, etc.; in industrial equipment manufacturing, it can serve as an important component of mechanical frames and piping systems; in the transportation industry, it can be used to manufacture parts for automobiles, trains, and other vehicles. We can customize bending fabrication parts of different specifications and shapes according to the needs of different industries.

Excellent Service Guarantee

We always put our customers first, providing comprehensive and high-quality services from product design and processing to after-sales service. Our technical team can provide professional design suggestions based on customer needs, ensuring the practicality and aesthetics of the products. At the same time, we strictly control every step of the production process to guarantee product quality and delivery time. If customers encounter any problems during use, our after-sales service team will respond promptly and solve the problems for them.

Our steel aluminum stainless steel bending fabrication parts provide customers with a one-stop solution through a wide selection of materials, precise processing technology, diverse application scenarios, and excellent service guarantees.

Product FAQ

Q

1. What is the customization process?

A

Q

2. How long does the product customization cycle take?

A

Q

3. Which materials can be customized hardware products?

A

Q

4. How accurate can customized products be?

A

Q

5. How to ensure the quality of customized products?

A

Customer reviews

Applications

Medical

Automotive

Aviation

Mobile Phone

Optics

Communications

Advantage-Why Choose Us?

High Accuracy

The precision of CNC machining parts can reach +-0.005mm, and small batches of goods can be fully inspected for each size to ensure that the size is within the tolerance range required by customers.

Rich Experience

The 20 years of OEM/ODM manufacturing experiences, we can not only more clearly understand the requirements of customer, but also provide customer with production solutions.

On time delivery

We will make production schedule for our customers when they order, timely feedback on production process, if there are any question, we will communication with customer ahead of schedule, maximum guarantee to customers on time delivery.

Certificates

Cases

The 20 years of OEM/ODM manufacturing experiences, we can not only more clearly understand the requirements of customer, but also provide customer with production solutions.

Consultation

We will contact you within one working day. Please pay attention to your email.

Related Products